#

Cleaning

#

Before use

Before using the Duofiller, to be sure its flow path is clean before the beverage is introduced we recommend the following cleaning procedure:

- Flush through the filler with lukewarm water. Start a fill in Timer Mode programming mode for flushing, the beverage valve will stay open until manually aborted. Contact time 5 minutes or more. If first-time use or if there are liquid residues in the tubes we recommend using PBW or a dishwasher detergent (at recommended concentration) and flush for 10 minutes.

- Flush through an acid-based sanitizer for beverage equipment (we recommend StarSan, SureSan or equivalent) at its recommended concentration. Contact time 3 minutes or more

- Gently spray (with a spray bottle) or soak the outside of the stainless fill tubes with an acid-based sanitizer. Use goggles. Contact time 3 minutes.

#

After use

After using the Duofiller with beverage it's mandatory to immediately do an in-line cleaning of the filler.

- Connect a keg with lukewarm water with a household food-grade detergent as PBW or dishwasher powder at its recommended concentration. Flush through the filler and ensure a contact time of 5 minutes or more.

- Flush through clean, lukewarm water to remove the detergent.

- Displace the liquid in the beverage lines by connecting the beverage line to the gas post of the keg (Make sure beverage valves are open). The CO2 from the keg will displace the liquid in the lines. You can either use a grey CO2 quick disconnect or you can use the black one by pushing it down on the gas post and just holding it there while the CO2 flows.

- Wipe off enclosure and fill tubes with a clean, damp cloth.

- Don't leave a liquid-filled can under the fill tubes for a long time (+1 hours). The capillary forces might draw the liquid into the CO2 system.

- Always depressurize the beverage hose and CO2 hose and disconnect power after use.

#

Periodical cleaning

Periodical in-line cleaning can be done with a suitable beer line cleaner as “Pipeline beer line cleaner” at its recommended concentration.

#

Enclosure cleaning

The stainless enclosure can be cleaned daily with a window cleaning spray and microfiber cloth to wipe off beverage, finger marks, detergent, sanitizer, etc. from the stainless enclosure. Use a stainless steel cleaner/polisher (Bar keepers friend) periodically to apply a protective coating to the casing making it less vulnerable to fingerprints etc. The front cover can also be disassembled and washed in a dishwasher if desired. Only use a small amount of detergent and never wash together with aluminum or other metals than stainless steel.

#

Cleaning the stainless CO2 tube

Keep the CO2 system dry at all times. Never connect liquid to the CO2 connector as it will damage the fill sensor. It's sufficient to spray the outside of the CO2 tube to clean it. If you want to clean the inside of the CO2 tube it can be disconnected and flushed or you can use a tube brush to clean it in place.

#

Sanitizing

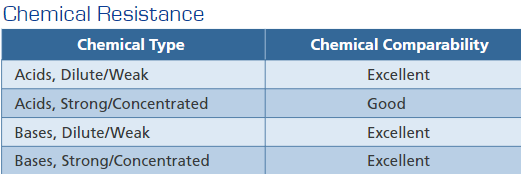

Use an acid based sanitizer (e.g. StarSan, SureSan) but only at the recommended concentration. Too high concentration of acid sanitizer can damage the plastic connectors. Contact us for chemical compatibility check if you want to use another sanitizer.

#

Disinfecting

If you use the filler for mixed fermentation fluids it might be desired to disinfect the filler after use. We recommend disassembling the beverage contact parts and boiling them in water. With the high-temperature add-on, all beverage contact parts can be boiled at 100C. If you don't have the high-temperature add-on don't boil the 2m beverage tube as it will deform and become unusable. Submerge the parts in water and boil, never flush with boiling water or steam, and the risk of personal injury would be too high.

Alternatively use a caustic disinfectant but please contact us for a chemical compatibility check if you want to use a disinfector. Don't use chlorine or strong acids.